Materials Test Lab Excellence: Revealing the Keys of Quality Control

Wiki Article

Comprehensive Products Screening Solutions for Quality Control

Thorough products testing services play a pivotal role in attaining this goal. Material failure evaluation allows for a much deeper understanding of why products may not meet the desired criteria, leading to enhanced quality control actions. With a expert and meticulous technique, extensive products testing solutions offer vital support to industries throughout various fields, ensuring the integrity and top quality assurance of frameworks, materials, and items.Strength and Resilience Testing

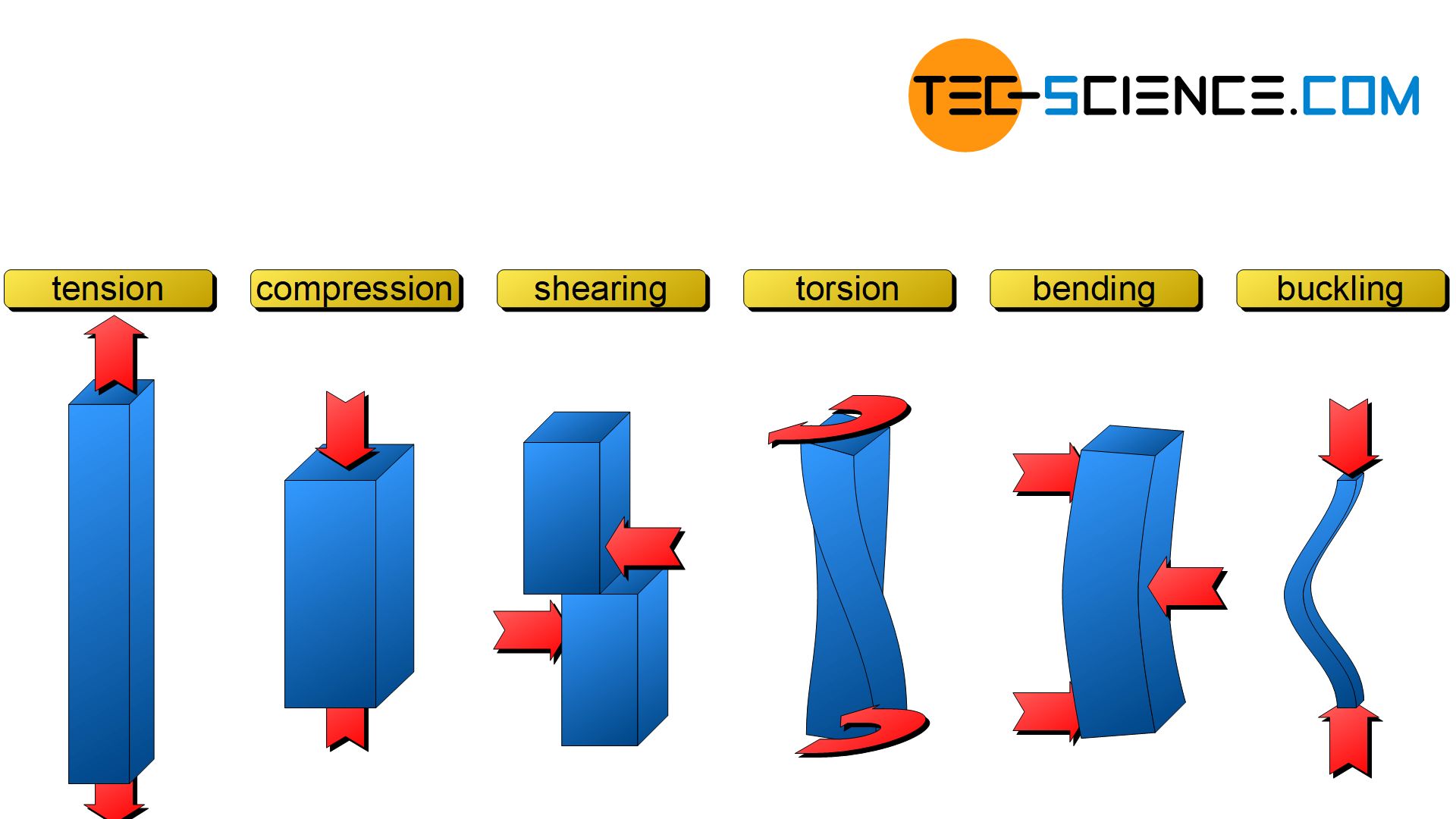

Toughness and resilience screening is a vital action in making certain the high quality and integrity of materials, as it enables the evaluation of their capability to hold up against ecological conditions and outside pressures. This kind of testing is vital in numerous industries, including building, auto, aerospace, and production.During stamina screening, materials go through various sorts of pressures, such as tension, compression, shear, and bending, to determine their mechanical homes and resistance to deformation. This assists makers recognize how materials will certainly do under real-world problems and make informed choices regarding their suitability for certain applications. By gauging criteria like return toughness, ultimate tensile strength, and modulus of elasticity, engineers can assess the material's performance and ensure it meets the needed requirements.

Chemical and Structure Evaluation

Chemical and make-up evaluation is an important facet of materials testing, continuing the examination from the previous subtopic by analyzing the essential makeup and molecular framework of products. This evaluation gives important understandings right into the chemical residential properties and make-up of a product, which is essential for understanding its behavior and performance in different applications.One crucial facet of chemical and make-up evaluation is the recognition and metrology of aspects existing in a material. This information assists identify the essential structure and purity of the material, ensuring it satisfies the needed requirements and criteria. In addition, it permits the detection of pollutants or trace elements that may affect the material's homes or performance.

Furthermore, chemical and make-up evaluation can supply info regarding the molecular structure of a material. This includes the arrangement and bonding of atoms, which affects the product's chemical and physical buildings. By understanding the molecular framework, engineers and scientists can make enlightened decisions about the viability of the material for details applications and determine any type of potential weak points or susceptabilities.

Non-Destructive Evaluating Approaches

Environmental and Weathering Screening

Environmental and weathering screening plays a vital function in examining the longevity and performance of materials in various conditions. materials test lab. This type of testing is crucial in identifying exactly how products will hold up against direct exposure to various environmental factors, such as temperature, humidity, UV radiation, and chemicals. By subjecting materials to these conditions in a controlled research laboratory setting, producers can get useful understandings right into their lasting efficiency and make educated choices about their suitability for particular applicationsOne of the key advantages of environmental and weathering testing is that it permits producers to assess the influence of these elements on the physical, mechanical, and chemical residential or commercial properties of products. Exposure to high temperatures can trigger materials to increase or contract, leading to dimensional adjustments and prospective failing.

Along with reviewing the durability of products, ecological and weathering screening likewise assists makers conform with market criteria and regulations. Numerous markets, such as auto, aerospace, and construction, have details demands for products utilized in their items. By carrying out screening according to these criteria, manufacturers can show the high quality and reliability of their products, offering clients confidence in their products.

Product Failure Analysis

The evaluation of material failing is an integral component of detailed materials examining solutions for quality control. Material failing can happen due to numerous aspects such as design imperfections, producing defects, incorrect use or upkeep, and environmental problems. The purpose of material failing evaluation is to identify the origin of the failing and offer understandings for enhancing the product's performance and resilience.Product failing analysis includes a systematic strategy that consists of aesthetic evaluation, non-destructive screening, and laboratory screening. Aesthetic evaluation permits the recognition of noticeable signs of failing such as cracks, contortions, or cracks. Non-destructive testing strategies, such as ultrasonic testing or X-ray assessment, can be used to identify interior imperfections without causing additional damages to the product. Laboratory screening entails conducting different examinations, such as mechanical testing, chemical evaluation, and microstructural evaluation, to understand the material's features and residential or commercial properties.

By examining product failings, suppliers can recognize weak factors in their visit homepage products and make needed enhancements to stop future failures. This helps in guaranteeing the quality and reliability of the materials made use of in numerous sectors such find out here as auto, aerospace, building and construction, and electronic devices. Furthermore, material failing evaluation plays a vital function in product development and top quality control, as it aids in choosing the best products and enhancing their performance.

Verdict

In verdict, detailed materials testing solutions are vital for high quality guarantee. These solutions consist of strength and longevity structure, chemical and screening analysis, non-destructive screening methods, ecological and weathering testing, and product failure analysis. By making use of these screening techniques, firms can make sure the quality and dependability of their products, resulting in boosted product efficiency and consumer fulfillment.Material failure evaluation allows for a deeper understanding of why products may not satisfy the wanted standards, leading to boosted quality control steps. With a thorough and expert technique, comprehensive materials testing solutions give vital assistance to industries across different markets, guaranteeing the stability and high quality look what i found guarantee of items, products, and frameworks.

The analysis of material failure is an integral part of extensive products examining solutions for top quality assurance. The purpose of material failure analysis is to identify the root cause of the failure and offer insights for enhancing the material's performance and toughness.

In addition, product failing evaluation plays a critical duty in item growth and top quality control, as it assists in selecting the best materials and optimizing their efficiency.

Report this wiki page